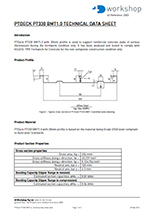

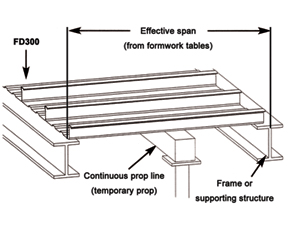

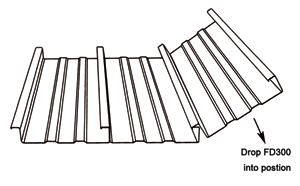

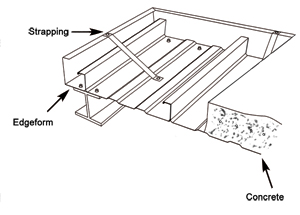

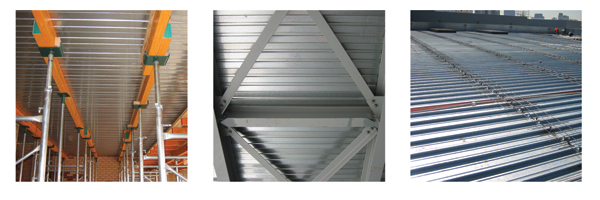

Temporary Propping Temporary propping, where required, must provide continuous transverse (across the sheet) support at the prescribed spacings. The prop bearer width must be no less than 100mm, unless established by calculation. Continuous support is generally provided by substantial timber or steel beams supported by vertical props. If the deck soffit is to be left exposed, it is recommended that a piece of caneite or similar be placed between the bearer and the deck. All propping should meet the requirements of AS3610. Prop bearers should not be placed higher than the permanent end support. Temporary propping must not be removed until the slab has cured sufficiently. Prop removal procedure should be in accordance with AS3610 and engineers recommendations. Decking Placement Formdeck 300 Decking is easily placed by hinging the overlap edge of one sheet over the underlap edge of the previous sheet. If the decking is used as a platform for laying subsequent sheets, designated propping must be positioned first. Fixing Once decking panels are laid they should immediately be secured against possible wind uplift. Typically use one fixing per pan at end supports, and one fixing every third pan at permanent internal supports. Self-drilling and tapping screws or powder actuated drive pins are commonly used. These fixings should be adjacent to the decking ribs. In the exposed conditions additional fixing may be required. Shear studs, if used, attached immediately after decking placement, or puddle welds, will provide wind uplift resistance. Slab Edgeforma Is a lightweight, easy to use, galvanised steel edge trim. It is made to the size of your slab height. |

|

Reinforcement Place the shrinking and temperature reinforcement (fabric) such that minimum cover requirements as per AS3600 is achieved. The fabric shall be properly lapped and tied to ensure continuity in both directions. If the slab has been designed as continuous, then additional steel reinforcement as specified Concrete Pouring Finally, the concrete must be poured evenly to the panel ends on prepared clean deck, in the direction of span of decking. Heaping of wet concrete must be avoided. The concrete should be placed in accordance with the requirements of AS3600 and have a minimum 28 day compressive strength f’c=25MPa and slump satisfying the Engineers requirements. As a guide the slump should be 60mm-80mm for vibrator compaction. Hand compaction is not recommended. Admixtures Chemical admixtures can be used provided they are in accordance with AS3600 (CI.19.1.1)

|

|